A condenser is a device that converts a high-temperature gas into a low-temperature liquid. It is used in a variety of processes, including air conditioning, refrigeration, and heat pumps. Here are some of the different types of condensers you may come across. The first kind of condenser is a shell-and-coil condenser, while the other two types are water-cooled and evaporative.

Shell-and-coil condensers

Two common types of marine condensers are shell-and-coil and coil-in-casing. Both use a steel shell tube filled with water, and the hot air from the inside liquefies on the tube’s surface. This type of condenser is generally used in large HVAC units, and requires a lot of space for condensing. The tubes can be easily cleaned using a brush, which is a great benefit when using this type of condenser.

Shell-and-tube condensers are the most common type of water-cooled condensers. These are easy to clean and repair, and contribute to the overall cost-effectiveness of a water-cooled chiller. Let’s discuss how they work. A shell-and-coil condenser consists of a steel tube and copper tubing. Water flows in and out of the tubes, and condenses on the outer surface of the tube, which drips to the bottom.

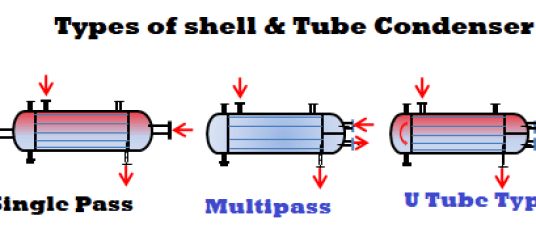

There are three basic types of Shell-and-coil condenser. The E-type shell is the most common. One tube passes through the exchanger, but two tube passes do not. In the latter case, the log mean temperature difference has to be corrected for the combined cocurrent and countercurrent flow. Alternatively, the front header can be replaced to make a large-diameter exchanger.

Water-cooled condensers

Unlike air-cooled condensers, which use ambient air to cool the refrigerant, water-cooled units require only water to cool. They are most commonly used in the exterior unit of rooftop and residential cooling systems. The difference between the two Types of condenser lies in their basic function. A water-cooled unit is generally more efficient, as it requires less maintenance. However, it is not the only benefit of this type of refrigeration unit.

To properly size a water-cooled unit, first determine the total heat rejection from the system. Normally, air-conditioning systems are sized according to horsepower, while high-backpressure systems are sized by the amount of refrigeration load per ton. One ton of refrigerant vapor has an air-conditioning load of approximately 12,000 BTU/hr. Add 3,000 BTU/hr for the heat of compression. For medium and low-temperature systems, add 3,000 BTU/hr to the horsepower.

One of the most common types of water-cooled condensers is the tube within-tube design. The inside tube circulates water and cools the refrigerant in the outside tube. This type of condenser can be cylindrical, spiral, or rectangular. This type of condenser is found in large chemical processing plants. The tube-and-tube condenser is composed of multiple straight tubes, with or without fins.

Evaporative condensers

There are many benefits to evaporative condensers, and some things simply cannot work without them. These cooling units convert high-pressure refrigerant vapor into liquid. They are essential to efficient air conditioning, heat pump systems, and refrigeration systems. Learn more about these cooling units with Linquip. Listed below are some of the advantages of evaporative condensers. This article explains the importance of evaporative condensers and how to choose one for your project.

The most common type of evaporative condenser is the forced-draft type, which pulls air through an opening at its base to condense it. The air is then released through a vent at the top. This type of condenser is available in axial or centrifugal fan designs, and each has its advantages and disadvantages. However, forced-draft evaporative condensers are generally more efficient than their counterparts.

A counterflow evaporative condenser is an efficient way to reduce condensation and fouling. In this type, water sprays fall over a metal coil while air flows up the unit. The fans are typically mechanically driven and can either be centrifugal or axial. Centrifugal fans are quieter and are ideal for both indoor and outdoor applications. They are also more durable than centrifugal fans.